There are, however, often different degrees of automation requirement in what is usually a complex process. Automation may not even be the answer when people, process and software are examined from an end-to-end perspective.

When considering whether automation is right for your organisation, here are some pointers.

- Temporary or Permanent? The changes in customer buying habits and delivery expectations during the global pandemic have certainly made every retailer review their internal processes. All have adapted in some way to the changing demands, but are these changes temporary, semi-permanent or permanent?

There are different types of ‘automation’ solution, depending on your answer. Does your automation need to be flexible or reversable? Is your solution in software, robots, new conveyor belts?

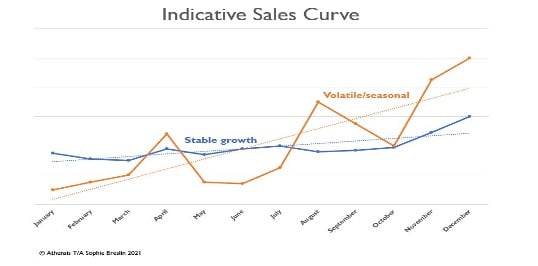

- Stable or Volatile/Seasonal Sales? Linked with the answer above, your sales curve has a major impact on whether automation is appropriate and, if so, the type of automation to deploy.

Critically, if the business is growing on a relatively predictable and stable trajectory, and you’ve predicted the growth curve accurately, then traditional automation may well be the smartest solution.

However, if your sales curve is more seasonally affected or your business acquisition plans are aggressive, then traditional automation may be a costly development which doesn’t properly solve the issue or give you a good ROI.

If your fulfilment demand varies significantly for just a couple of months a year, is the better solution to have an adaptable workflow process? Such as employing more people during the busy periods (and know when and how to implement) or having flexible automation to better manage fulfilment to your customer in the short-term.

Recognising how agile your solution needs to be, may make you question whether automation is right at all.

- Your Future Plans? Traditional automation, that is fixed in location, has advantages for organisations that have a relatively consistent sales curve, with a network of distribution centres that can be expanded in a controlled manner. Disadvantages are that growth can be limited by automation that does not flex easily.

Organisations that need to respond in an agile way to market demand or have an ambitious growth curve (such as acquisition of other businesses with different SKU lines) might consider agile automation that can be configured to respond to changing environments, locations and demands

This has the added advantage of capital investment being portable, so that if you outgrow your building your automation can move with you.

Paul Cusack, National Industry Sales Manager at Omron UK explains:

“Autonomous Mobile Robots (AMRs) are a growing technology that is creating much excitement in the logistics world. However, it is important to understand that, while offering immense flexibility, they are not a silver bullet. AMRs come into their own in environments with high degrees of variability where SKUs have little uniformity in terms of both physical attributes and consumer demand.”

He goes on to say…

“Simultaneous Localisation and Mapping (SLAM) enables seamless integration with existing infrastructure and, crucially, safe operation in collaboration with human workers enabling logistics providers to vary capacity quickly and easily to meet rapidly changing consumer demand.”

And finally, an automated solution can only ever be as good as the predictions you make.

Without accurate forecasting and thinking through the processes end-to-end, the goals to improve delivery efficiency, customer satisfaction and profitability can be undermined by poor investment decisions.

If you would like help in determining if or which automation is best for your organisation or to evaluate current systems, look for ideas here and call me on 07879 893 338.

To learn more about Omron’s AMR capability visit here.